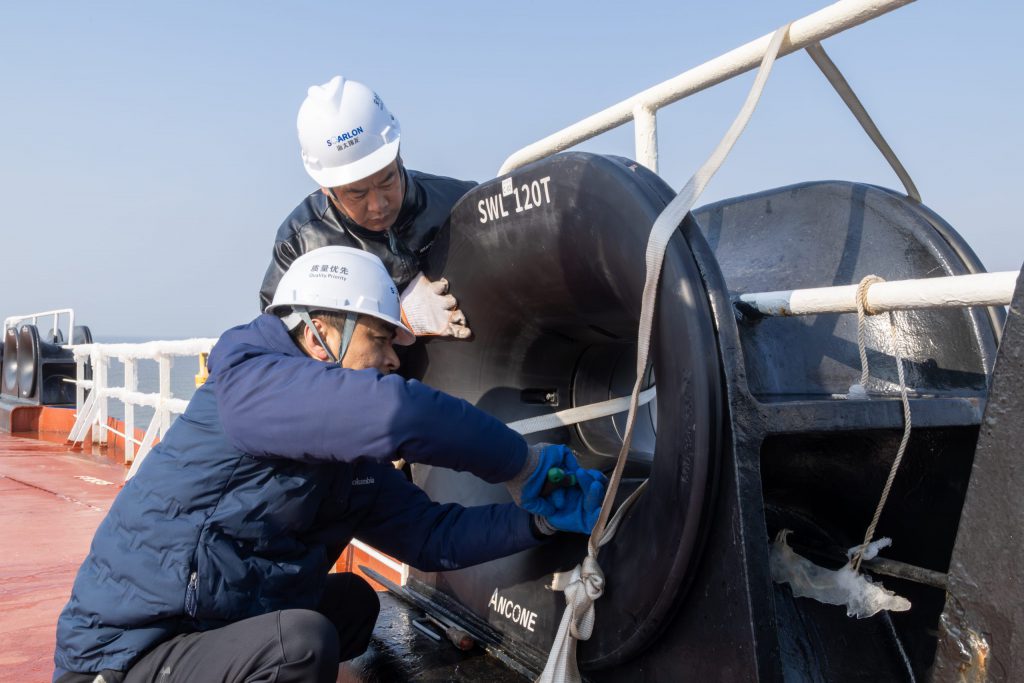

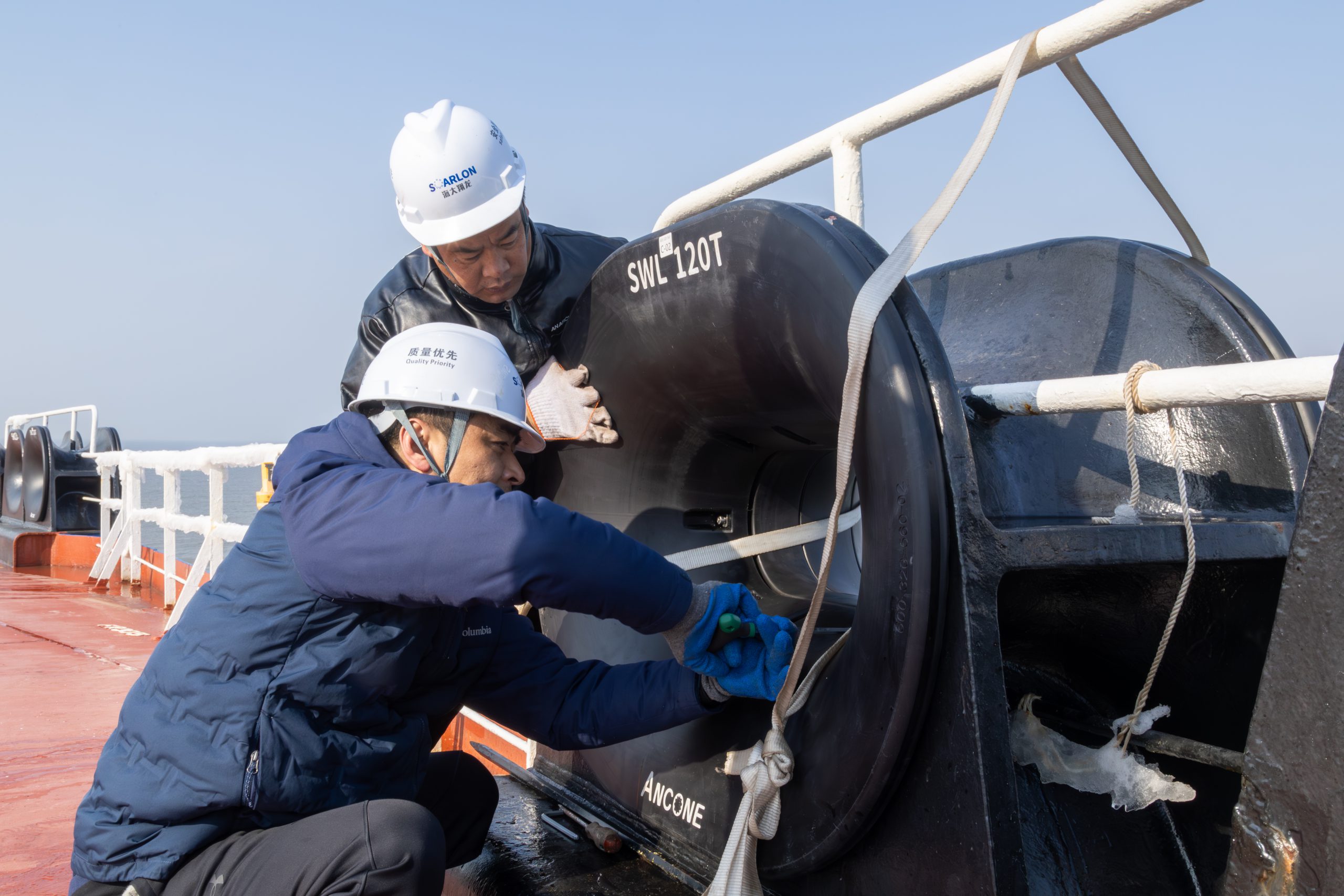

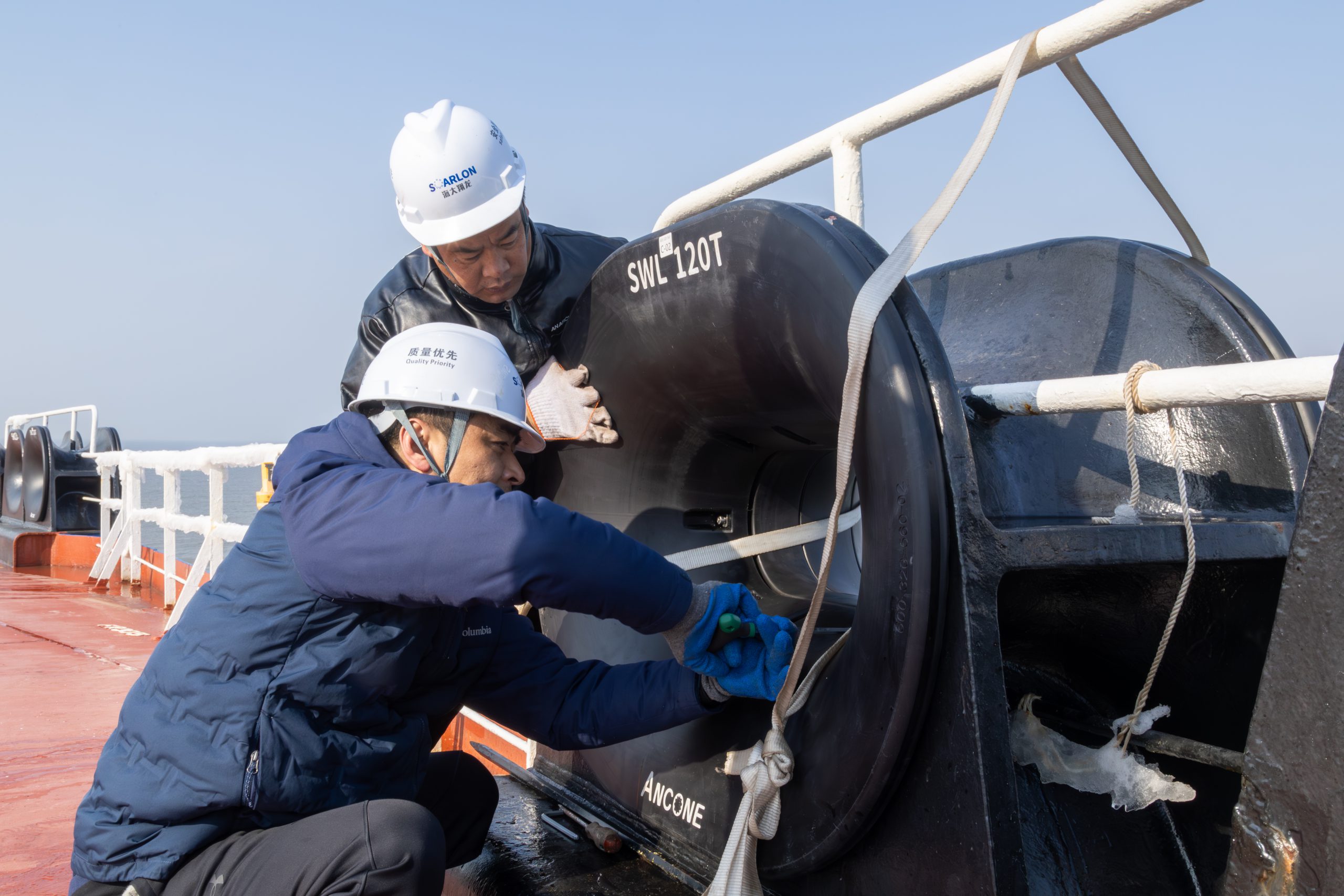

Installation Site

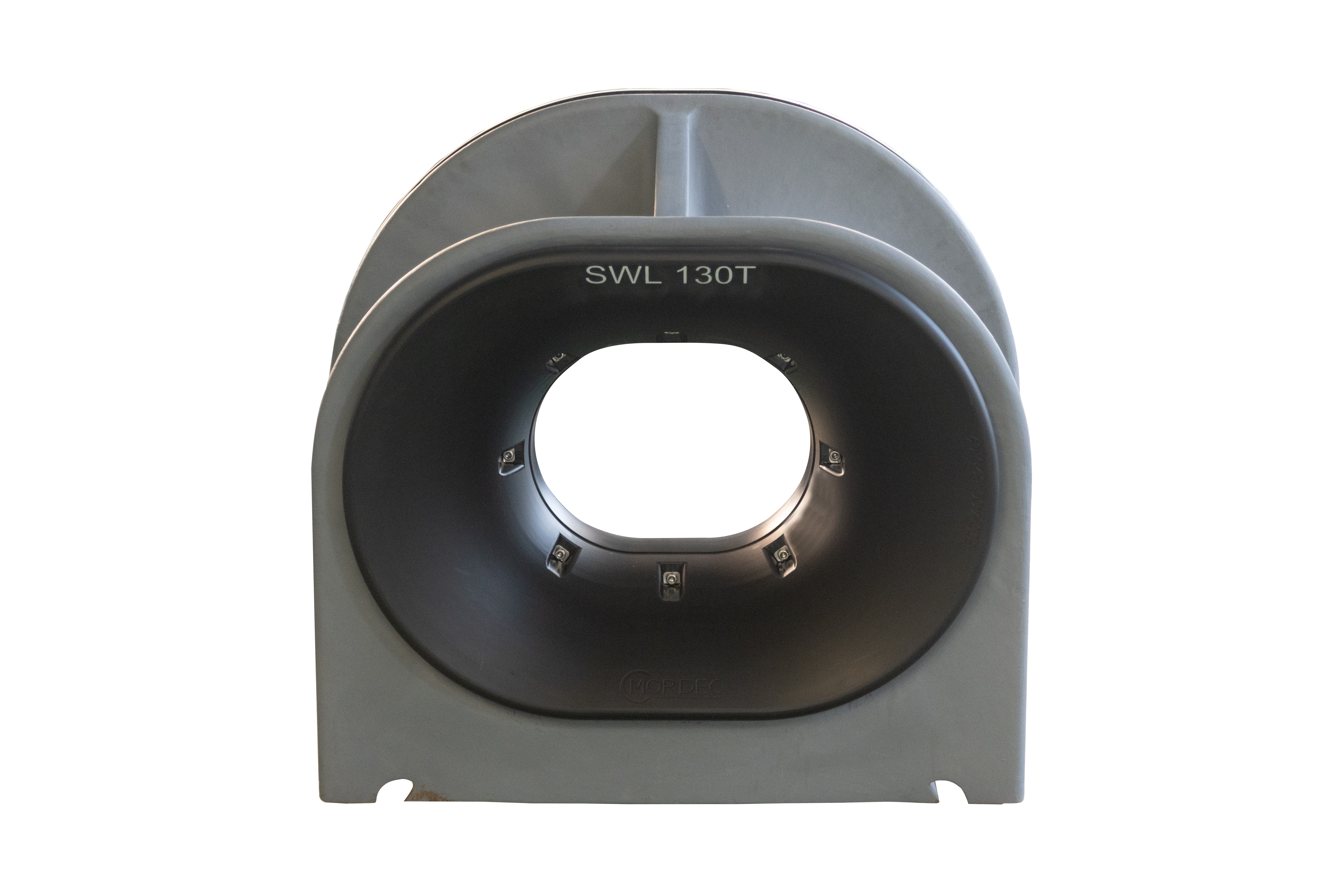

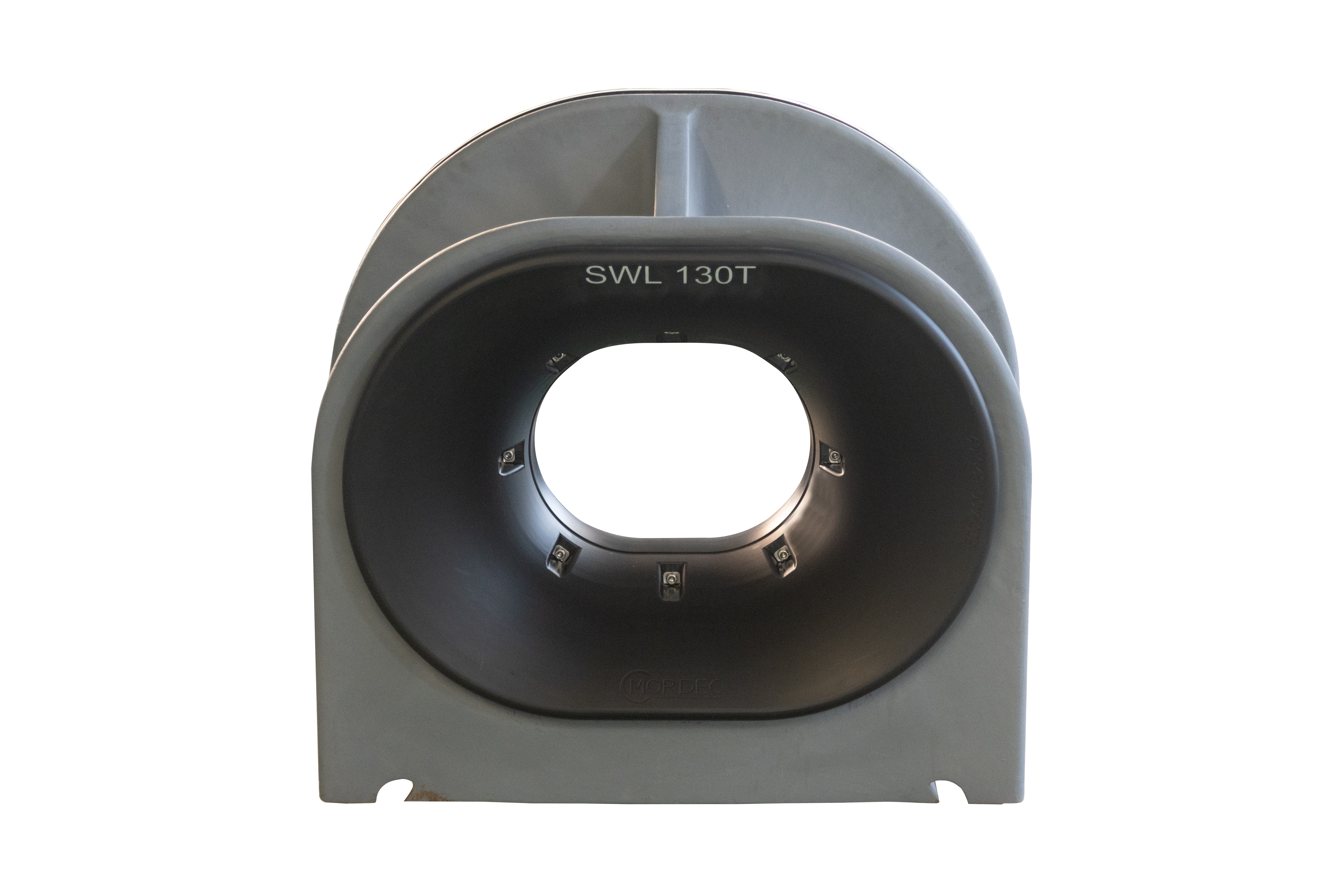

Comparison of the Installation and Non-installation of SOARLON Polymer Insert

Comparison of the Wear of Polymer Mooring Rope with and without the Use of an Insert

After Installing the Insert

Without Installing the Insert

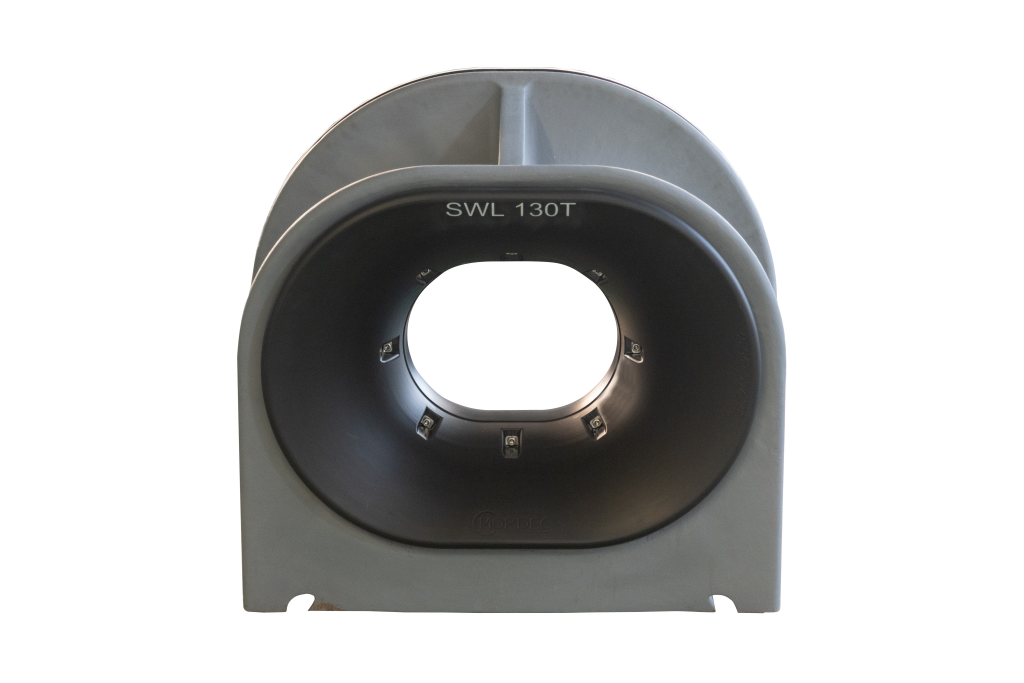

Product Introduction of SOARLON Polymer Insert

The polymer insert of a ship is a crucial component installed on the inner wall of the chock, mainly used to protect the mooring rope and the structure of the chock. Its advantages are mainly reflected in aspects such as material properties, functionality, and economy, as follows:

I. Main Advantages

1.Protecting the Mooring Rope

– Reducing Wear and Tear: The polymer insert is made of polymer materials (such as ultra-high molecular weight polyethylene, nylon, polyurethane, etc.). With a smooth and wear-resistant surface, it can effectively reduce the friction between the mooring rope and the chock, thus extending the service life of the mooring rope.

– Preventing Cutting: The high toughness of the polymer insert can prevent the mooring rope from being cut or damaged due to direct contact with the edge of the metal chock.

2.Protecting the Structure of the Chock

– Impact Resistance: The polymer insert can absorb the impact force when the mooring rope is dragged, reducing the direct impact on the metal structure of the chock and avoiding deformation or damage.

– Corrosion Prevention: The polymer materials are resistant to the corrosion of seawater and salt spray, preventing the metal chock from rusting due to long-term exposure to the marine environment.

3.Improving Operational Efficiency

– Reducing the Friction Coefficient: The surface of the polymer insert is smooth and has self-lubricating properties, making the dragging process of the mooring rope smoother, reducing the occurrence of jams, and enhancing operational efficiency.

– Reducing Maintenance: The wear resistance and corrosion resistance of the polymer insert reduce the maintenance frequency of the chock, saving time and costs.

4.Lightweight Design

– Light Weight: The polymer materials have a low density, and the weight of the polymer insert is much lower than that of metal materials. It reduces the load of the ship, which is beneficial for energy conservation and stability.

– Easy Installation: The lightweight feature makes the installation and replacement of the polymer insert more convenient, reducing the downtime.

5.Environmental Resistance Performance

– Corrosion Resistance: The polymer materials have excellent corrosion resistance against seawater, oil stains, chemicals, etc., and are suitable for long-term use in harsh marine environments.

– Temperature Resistance: It can still maintain stable performance in high-temperature or low-temperature environments, avoiding deformation or failure caused by temperature changes.

6.Economy

– Extending the Service Life of Equipment: The polymer insert protects the mooring rope and the chock, reducing the frequency of replacement and maintenance, and lowering the long-term operation costs.

– High Cost-effectiveness: Although the initial cost may be relatively high, its long service life and low-maintenance characteristics make its comprehensive cost lower.

7.Safety

– Anti-slip and Buffering: The surface design of the polymer insert can increase the friction force, preventing the mooring rope from slipping. At the same time, it can buffer the impact force when the mooring rope is dragged, improving the safety of the operation.

– Insulation: Some polymer materials have insulating properties, reducing potential safety hazards during the operation of electrical equipment.

II. Typical Application Scenarios

– Mooring chock of ships

– Mooring rope guiding devices in port terminals

– Mooring rope guiding systems of offshore platforms

In summary, through its excellent material properties and functional design, the polymer insert significantly extends the service life of the mooring rope and the chock, reduces maintenance costs, and improves operational efficiency and safety at the same time. It is an indispensable and important component in modern shipbuilding and marine engineering.

We can customize different size specifications and load-bearing capacities according to your needs.

Installation Site

Comparison of the Installation and Non-installation of SOARLON Polymer Insert

Comparison of the Wear of Polymer Mooring Rope with and without the Use of an Insert

After Installing the Insert

Without Installing the Insert

Product Introduction of SOARLON Polymer Insert

The polymer insert of a ship is a crucial component installed on the inner wall of the chock, mainly used to protect the mooring rope and the structure of the chock. Its advantages are mainly reflected in aspects such as material properties, functionality, and economy, as follows:

I. Main Advantages

1.Protecting the Mooring Rope

– Reducing Wear and Tear: The polymer insert is made of polymer materials (such as ultra-high molecular weight polyethylene, nylon, polyurethane, etc.). With a smooth and wear-resistant surface, it can effectively reduce the friction between the mooring rope and the chock, thus extending the service life of the mooring rope.

– Preventing Cutting: The high toughness of the polymer insert can prevent the mooring rope from being cut or damaged due to direct contact with the edge of the metal chock.

2.Protecting the Structure of the Chock

– Impact Resistance: The polymer insert can absorb the impact force when the mooring rope is dragged, reducing the direct impact on the metal structure of the chock and avoiding deformation or damage.

– Corrosion Prevention: The polymer materials are resistant to the corrosion of seawater and salt spray, preventing the metal chock from rusting due to long-term exposure to the marine environment.

3.Improving Operational Efficiency

– Reducing the Friction Coefficient: The surface of the polymer insert is smooth and has self-lubricating properties, making the dragging process of the mooring rope smoother, reducing the occurrence of jams, and enhancing operational efficiency.

– Reducing Maintenance: The wear resistance and corrosion resistance of the polymer insert reduce the maintenance frequency of the chock, saving time and costs.

4.Lightweight Design

– Light Weight: The polymer materials have a low density, and the weight of the polymer insert is much lower than that of metal materials. It reduces the load of the ship, which is beneficial for energy conservation and stability.

– Easy Installation: The lightweight feature makes the installation and replacement of the polymer insert more convenient, reducing the downtime.

5.Environmental Resistance Performance

– Corrosion Resistance: The polymer materials have excellent corrosion resistance against seawater, oil stains, chemicals, etc., and are suitable for long-term use in harsh marine environments.

– Temperature Resistance: It can still maintain stable performance in high-temperature or low-temperature environments, avoiding deformation or failure caused by temperature changes.

6.Economy

– Extending the Service Life of Equipment: The polymer insert protects the mooring rope and the chock, reducing the frequency of replacement and maintenance, and lowering the long-term operation costs.

– High Cost-effectiveness: Although the initial cost may be relatively high, its long service life and low-maintenance characteristics make its comprehensive cost lower.

7.Safety

– Anti-slip and Buffering: The surface design of the polymer insert can increase the friction force, preventing the mooring rope from slipping. At the same time, it can buffer the impact force when the mooring rope is dragged, improving the safety of the operation.

– Insulation: Some polymer materials have insulating properties, reducing potential safety hazards during the operation of electrical equipment.

II. Typical Application Scenarios

– Mooring chock of ships

– Mooring rope guiding devices in port terminals

– Mooring rope guiding systems of offshore platforms

In summary, through its excellent material properties and functional design, the polymer insert significantly extends the service life of the mooring rope and the chock, reduces maintenance costs, and improves operational efficiency and safety at the same time. It is an indispensable and important component in modern shipbuilding and marine engineering.

We can customize different size specifications and load-bearing capacities according to your needs.

Installation Site

Comparison of the Installation and Non-installation of SOARLON Polymer Insert

Comparison of the Wear of Polymer Mooring Rope with and without the Use of an Insert

After Installing the Insert

Without Installing the Insert

1.Protecting the Mooring Rope

– Reducing Wear and Tear: The polymer insert is made of polymer materials (such as ultra-high molecular weight polyethylene, nylon, polyurethane, etc.). With a smooth and wear-resistant surface, it can effectively reduce the friction between the mooring rope and the chock, thus extending the service life of the mooring rope.

– Preventing Cutting: The high toughness of the polymer insert can prevent the mooring rope from being cut or damaged due to direct contact with the edge of the metal chock.

2.Protecting the Structure of the Chock

– Impact Resistance: The polymer insert can absorb the impact force when the mooring rope is dragged, reducing the direct impact on the metal structure of the chock and avoiding deformation or damage.

– Corrosion Prevention: The polymer materials are resistant to the corrosion of seawater and salt spray, preventing the metal chock from rusting due to long-term exposure to the marine environment.

3.Improving Operational Efficiency

– Reducing the Friction Coefficient: The surface of the polymer insert is smooth and has self-lubricating properties, making the dragging process of the mooring rope smoother, reducing the occurrence of jams, and enhancing operational efficiency.

– Reducing Maintenance: The wear resistance and corrosion resistance of the polymer insert reduce the maintenance frequency of the chock, saving time and costs.

4.Lightweight Design

– Light Weight: The polymer materials have a low density, and the weight of the polymer insert is much lower than that of metal materials. It reduces the load of the ship, which is beneficial for energy conservation and stability.

– Easy Installation: The lightweight feature makes the installation and replacement of the polymer insert more convenient, reducing the downtime.

5.Environmental Resistance Performance

– Corrosion Resistance: The polymer materials have excellent corrosion resistance against seawater, oil stains, chemicals, etc., and are suitable for long-term use in harsh marine environments.

– Temperature Resistance: It can still maintain stable performance in high-temperature or low-temperature environments, avoiding deformation or failure caused by temperature changes.

6.Economy

– Extending the Service Life of Equipment: The polymer insert protects the mooring rope and the chock, reducing the frequency of replacement and maintenance, and lowering the long-term operation costs.

– High Cost-effectiveness: Although the initial cost may be relatively high, its long service life and low-maintenance characteristics make its comprehensive cost lower.

7.Safety

– Anti-slip and Buffering: The surface design of the polymer insert can increase the friction force, preventing the mooring rope from slipping. At the same time, it can buffer the impact force when the mooring rope is dragged, improving the safety of the operation.

– Insulation: Some polymer materials have insulating properties, reducing potential safety hazards during the operation of electrical equipment.

Typical Application Scenarios

– Mooring chock of ships

– Mooring rope guiding devices in port terminals

– Mooring rope guiding systems of offshore platforms

We can customize different size specifications and load-bearing capacities according to your needs.