Product Introduction of SOARLON Water-lubricated Bearing

The water-lubricated stern bearing of a ship is a crucial component in the ship’s propulsion system, mainly used to support the propeller shaft and transmit power. Using water as the lubricating medium, it replaces the traditional oil-lubrication method and has unique design and performance advantages.

I. Main Advantages

1.Remarkable Environmental Friendliness

– No Risk of Oil Pollution:SOARLON water lubrication eliminates the risk of marine environmental pollution caused by lubricating oil leakage (for example, oil may damage the ecosystem or violate environmental protection regulations), and it is especially suitable for sensitive water areas.

–Compliance with International Standards:It meets the strict requirements of institutions such as the IMO (International Maritime Organization) for ship emissions, reducing the risk of environmental protection penalties.

2.Low Operation Cost

–Elimination of the Complex Oil Circuit System: There is no need for auxiliary equipment such as oil pumps, oil tanks, and filters, which simplifies the structure and reduces the construction and maintenance costs.

–Convenient Maintenance:During daily inspections, only the wear condition of the bearing needs to be paid attention to. There is no need to frequently replace or replenish lubricating oil, saving labor and material costs.

3.High-efficiency Cooling and High-temperature Resistance

–High Specific Heat Capacity of Water:It can quickly carry away the heat generated by friction, preventing the bearing from overheating. It is especially suitable for high-load working conditions (such as high-speed navigation or heavily loaded ships).

–Avoidance of High-temperature Failure in Oil Lubrication:Traditional lubricating grease is prone to oxidation and failure at high temperatures. However, water has stable performance at room temperature, offering higher reliability.

4.Simplified Structure and High Reliability

–No Sealing Requirement:Water-lubricated bearings usually adopt an open design, avoiding the complex shaft sealing system required for oil lubrication and reducing the failures caused by sealing failures.

–Material Adaptability:They are commonly made of rubber, polymers, or composite materials, which are wear-resistant and have good compatibility with water, reducing the risk of corrosion.

5.Wide-range Environmental Adaptability

–Natural Utilization of Seawater/Freshwater: It directly pumps the water from the surrounding water area as a lubricant without the need for additional storage of the medium, which is especially suitable for ocean-going vessels.

–Sediment Resistance: Some designs allow a small amount of particulate matter to pass through, preventing blockage caused by turbid water quality (a filtration system is required to optimize the service life).

II. Core Functions

1.Support and Power Transmission

–Bearing the Weight of the Propeller Shaft: It ensures that the propeller shaft remains centered during high-speed rotation, reducing vibration and uneven wear.

–Transmitting Propulsion Force: It transmits the thrust generated by the propeller to the hull structure through the bearing, propelling the ship forward.

2.Lubrication and Friction Reduction

–Formation of the Water Film: A hydrodynamic water film is formed between the shaft and the bearing, reducing the direct contact between metals (or composite materials), decreasing the friction coefficient, and prolonging the service life.

–Self-healing Property: Some materials (such as rubber) can restore the sealing performance through elastic deformation after slight wear, maintaining the lubrication effect.

3.Cooling and Thermal Management

–Continuous Heat Dissipation: When water flows through the bearing clearance, it takes away the frictional heat and the heat transferred from the engine, preventing jamming or damage caused by the thermal expansion of materials.

4.Vibration and Noise Control

–Damping Effect: The water film and elastic bearing materials (such as rubber) can absorb high-frequency vibrations and reduce the underwater radiated noise, which is particularly important for the stealth performance of military ships.

5.Self-cleaning and Anti-pollution

–Scouring Action: The continuous flow of water can wash away the wear debris or foreign objects, reducing the accumulation of impurities inside the bearing and decreasing the risk of abnormal wear.

III. Applicable Scenarios and Limitations

–Applicable Ship Types: It is commonly used in scenarios where environmental protection or noise sensitivity is required, such as small and medium-sized merchant ships, scientific research vessels, military ships, etc.

–Limiting Factors: High-load ships (such as large tankers) may still require oil lubrication to cope with extreme pressures.

When the water quality is poor (such as containing a large amount of sediment), the filtration needs to be strengthened; otherwise, it may accelerate the wear of the bearing.

IV. Technological Development Trends

–Material Innovation: Develop composite materials (such as ceramic-reinforced polymers) with higher wear resistance and a lower friction coefficient.

–Intelligent Monitoring: Integrate sensors to monitor the temperature, vibration, and wear status of the bearing in real time, enabling predictive maintenance.

–Hybrid Lubrication Technology: Combine water with a small amount of environmentally friendly lubricant under specific working conditions to further enhance the performance under extreme conditions.

In summary, by skillfully utilizing water as the medium, the water-lubricated stern bearing of a ship achieves a balance among environmental friendliness, economic efficiency, and reliability, making it a preferred option in the design of modern green ships. Its functions are not limited to the mechanical support provided by traditional bearings, but also extend to the fields of environmental protection and energy efficiency optimization, reflecting the trend of the shipbuilding industry’s transformation towards sustainable development.

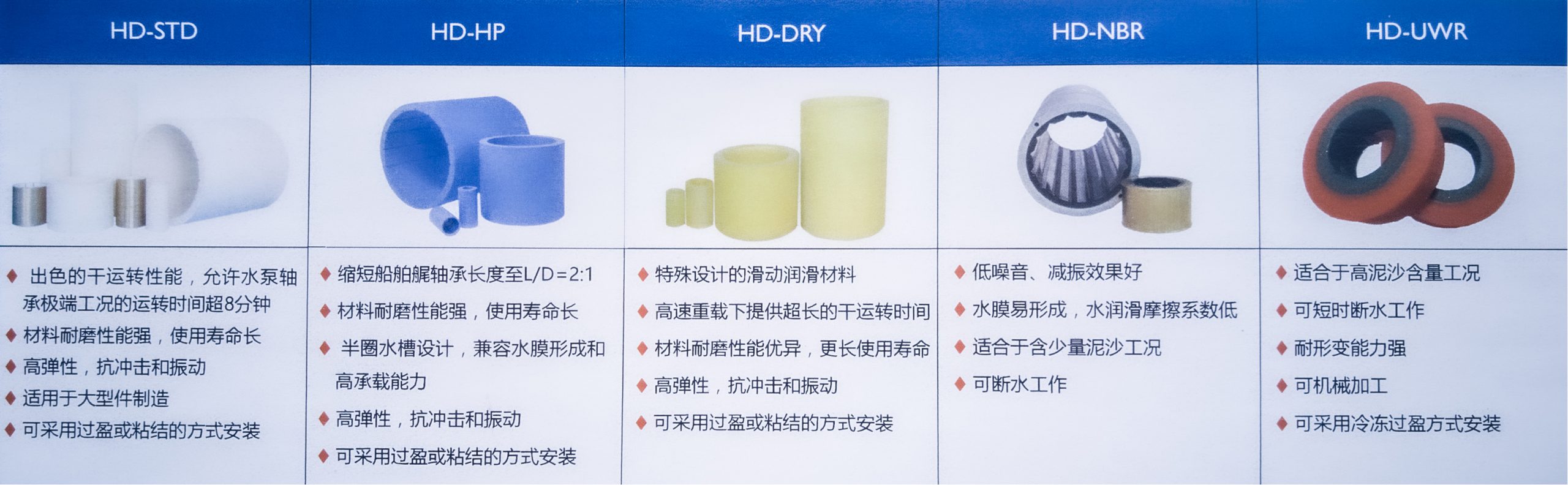

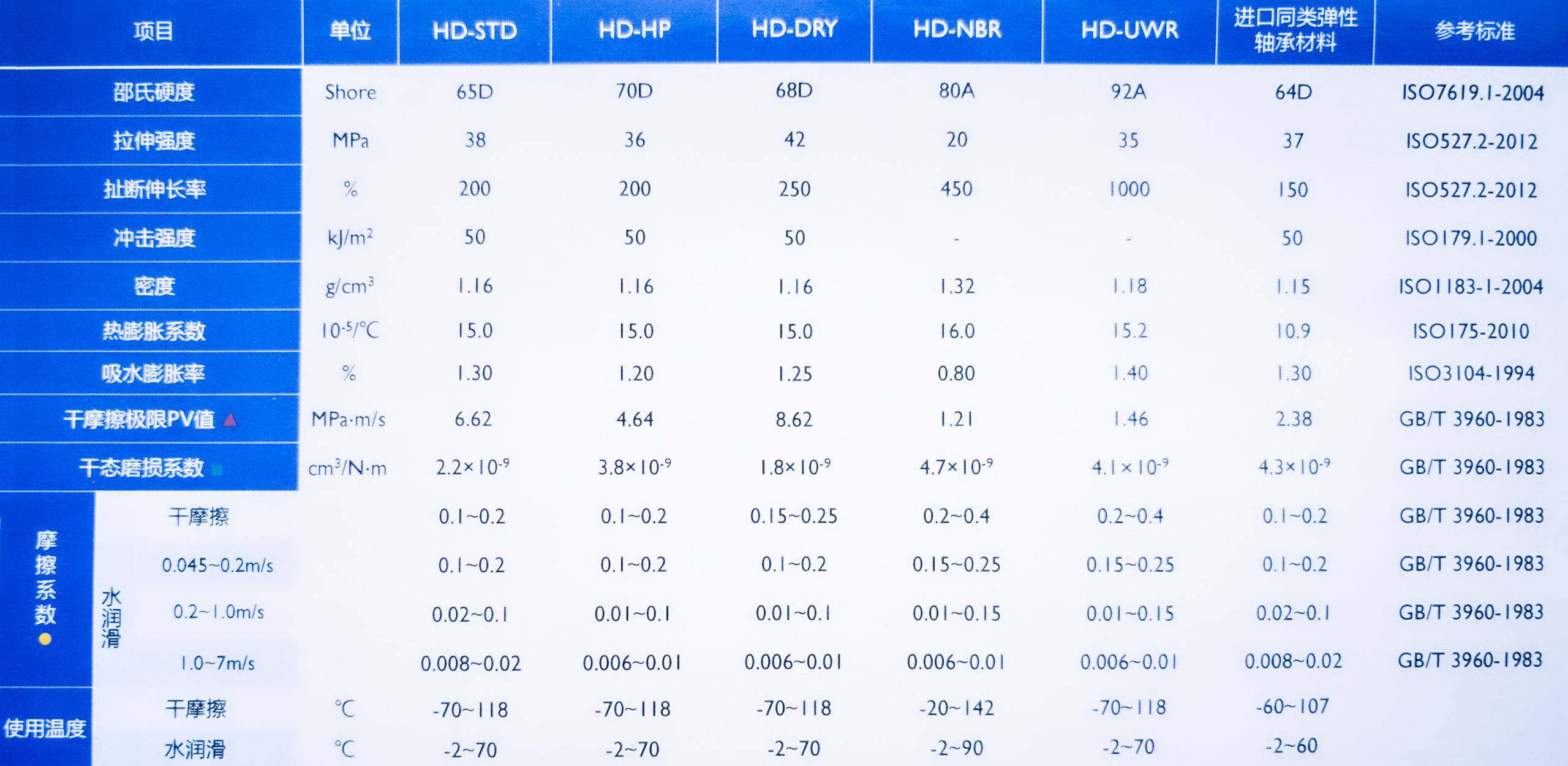

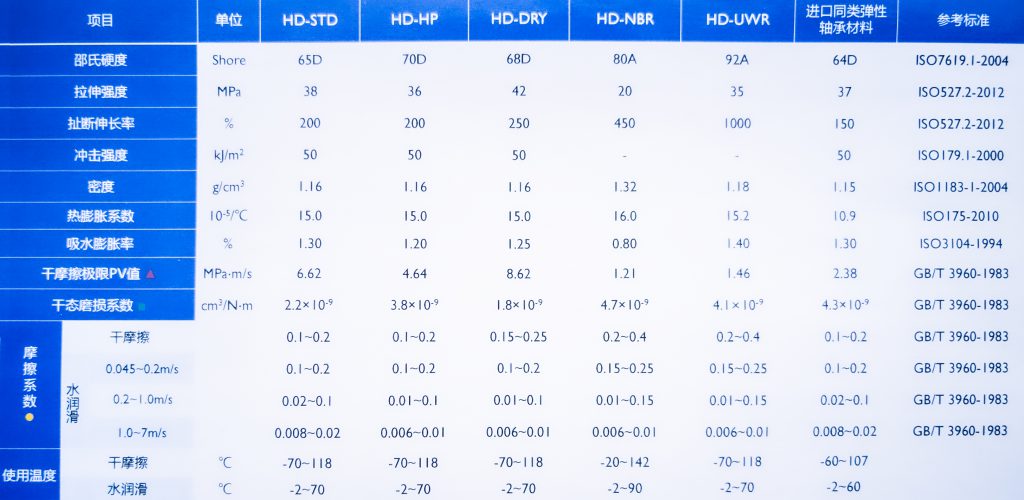

Material List

Different materials can play distinct roles in various fields.

Experimental Report Form

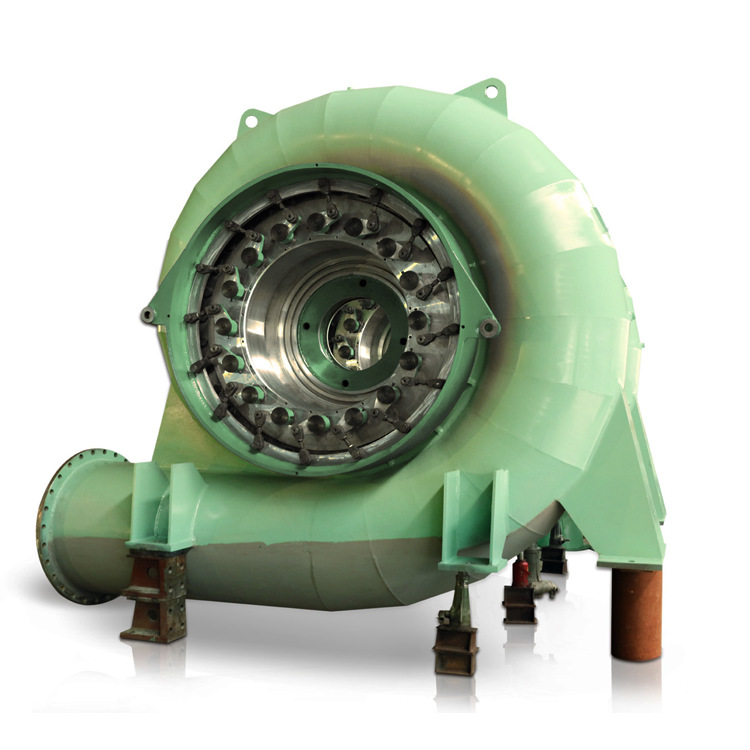

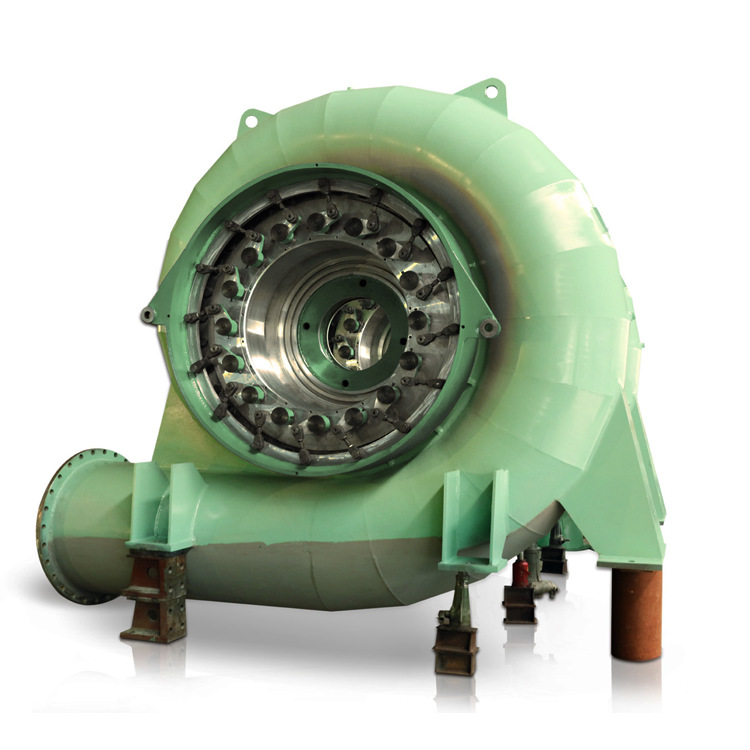

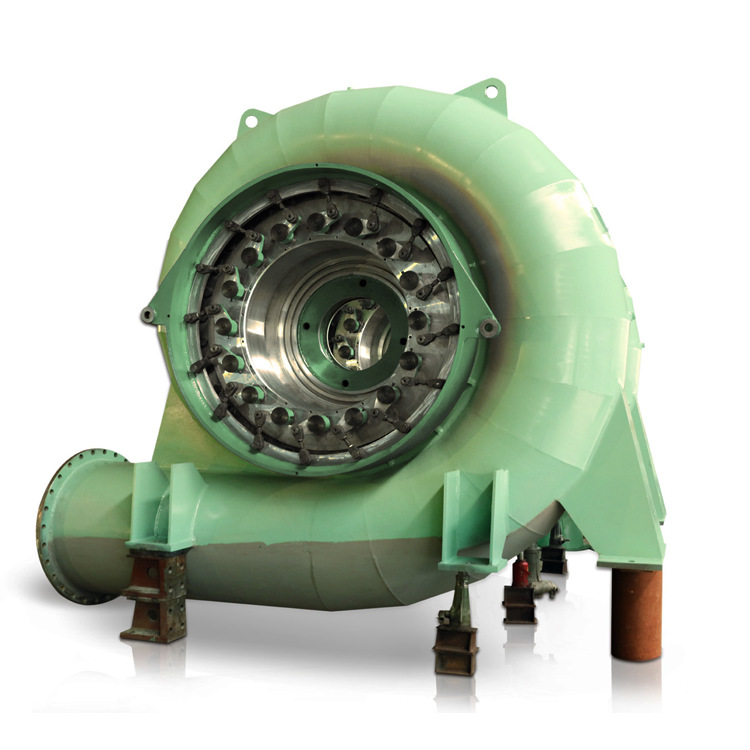

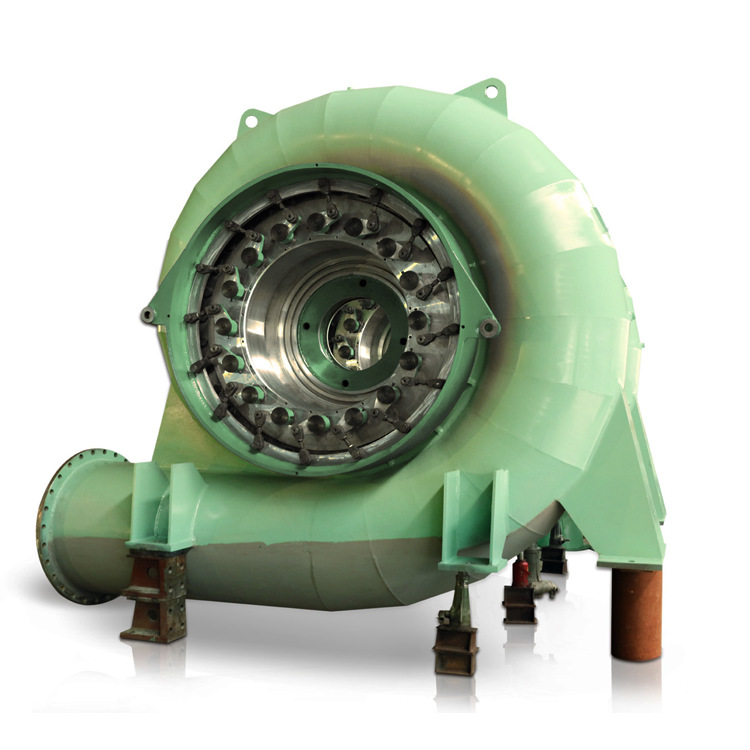

In the field of turbines, SOARLON bearings offer two models, HD-STD and HD-DRY, to meet customers’ different requirements for operating conditions and safety levels. HD-STD features high cost-effectiveness, while HD-DRY has a higher safety level. For small-sized bearings, such as guide vane connecting rod bearings, SOARLON supplies them as integral bearings. For large-sized bearings, such as main shaft guide bearings, SOARLON provides them in the form of bearing shells.

HD-STD, HD-DRY, and HD-UWR are SOARLON bearing products specifically designed for propeller shaft systems. Among them, the HD-STD type is suitable for ocean-going vessels sailing in clean water environments. The HD-DRY type is applicable to inland-river vessels navigating in waters with poor water quality and containing sediment. The HD-UWR type is especially suitable for use as the cutter bearings of dredgers. The above-mentioned models can be provided in various structures such as integral, single tapered key, and slat types to meet design requirements.

Practice has proved that when the HD-STD type SOARLON bearing is used as a stern roller bearing, it not only has a long service life and excellent impact resistance, but can also work normally under the designed ultimate towing force. When the HD-STD is used as a stern roller bearing, according to the design requirements, it can be lubricated with circulating water or grease. Products with a size ranging from 400 to 1500 mm can be customized according to customers’ needs.

For the special working conditions of rudder bearings, such as low-speed swinging and the difficulty in establishing a lubrication film, it is recommended to use the HD-STD type SOARLON bearing. For special vessels with high requirements for reliability, the HD-DRY type SOARLON bearing with a higher safety level can be used.

Both of these two types of bearings have self-lubricating properties. Even in the case of water interruption, they can work for a long time, fully meeting the usage requirements of rudder bearings.

SOARLON coating has excellent resistance to the marine environment, and it has good adaptability to working conditions such as sudden temperature rises and drops, sudden pressure changes, and variations in acidic and alkaline environments. Based on years of application experience in engineering cases, the SOARLON coating can protect the stern shaft from seawater corrosion for up to 10 years. Compared with traditional fiberglass winding, the SOARLON coating can be applied on-site, simplifying the construction process and saving costs.

In the field of water pumps, the HD-STD type bearing is the most widely used, mainly serving as a guide bearing in vertical water pumps such as deep well long shaft pumps, mixed flow pumps, axial flow pumps, and feed water pumps. The HD-STD type SOARLON bearing allows for a dry start-up time that is more than five times longer than that of similar foreign products, providing a strong guarantee for the highly reliable operation of water pumps under extremely harsh working conditions such as frequent start-stop operations and long periods of water interruption.

We can customize different size specifications and load-bearing capacities according to your needs.

1.Remarkable Environmental Friendliness

-No Risk of Oil Pollution:SOARLON water lubrication eliminates the risk of marine environmental pollution caused by lubricating oil leakage (for example, oil may damage the ecosystem or violate environmental protection regulations), and it is especially suitable for sensitive water areas.

-Compliance with International Standards: It meets the strict requirements of institutions such as the IMO (International Maritime Organization) for ship emissions, reducing the risk of environmental protection penalties.

2.Low Operation Cost

-Elimination of the Complex Oil Circuit System: There is no need for auxiliary equipment such as oil pumps, oil tanks, and filters, which simplifies the structure and reduces the construction and maintenance costs.

-Convenient Maintenance: During daily inspections, only the wear condition of the bearing needs to be paid attention to. There is no need to frequently replace or replenish lubricating oil, saving labor and material costs.

3.High-efficiency Cooling and High-temperature Resistance

-High Specific Heat Capacity of Water: It can quickly carry away the heat generated by friction, preventing the bearing from overheating. It is especially suitable for high-load working conditions (such as high-speed navigation or heavily loaded ships).

-Avoidance of High-temperature Failure in Oil Lubrication: Traditional lubricating grease is prone to oxidation and failure at high temperatures. However, water has stable performance at room temperature, offering higher reliability.

4.Simplified Structure and High Reliability

-No Sealing Requirement: Water-lubricated bearings usually adopt an open design, avoiding the complex shaft sealing system required for oil lubrication and reducing the failures caused by sealing failures.

-Material Adaptability: They are commonly made of rubber, polymers, or composite materials, which are wear-resistant and have good compatibility with water, reducing the risk of corrosion.

5.Wide-range Environmental Adaptability

-Natural Utilization of/Seawater/Freshwater: It directly pumps the water from the surrounding water area as a lubricant without the need for additional storage of the medium, which is especially suitable for ocean-going vessels.

-Sediment Resistance: Some designs allow a small amount of particulate matter to pass through, preventing blockage caused by turbid water quality (a filtration system is required to optimize the service life).

1.Support and Power Transmission

– Bearing the Weight of the Propeller Shaft: It ensures that the propeller shaft remains centered during high-speed rotation, reducing vibration and uneven wear.

– Transmitting Propulsion Force: It transmits the thrust generated by the propeller to the hull structure through the bearing, propelling the ship forward.

2.Lubrication and Friction Reduction

– Formation of the Water Film: A hydrodynamic water film is formed between the shaft and the bearing, reducing the direct contact between metals (or composite materials), decreasing the friction coefficient, and prolonging the service life.

– Self-healing Property: Some materials (such as rubber) can restore the sealing performance through elastic deformation after slight wear, maintaining the lubrication effect.

3.Cooling and Thermal Management

– Continuous Heat Dissipation: When water flows through the bearing clearance, it takes away the frictional heat and the heat transferred from the engine, preventing jamming or damage caused by the thermal expansion of materials.

4.Vibration and Noise Control

– Damping Effect: The water film and elastic bearing materials (such as rubber) can absorb high-frequency vibrations and reduce the underwater radiated noise, which is particularly important for the stealth performance of military ships.

5.Self-cleaning and Anti-pollution

– Scouring Action: The continuous flow of water can wash away the wear debris or foreign objects, reducing the accumulation of impurities inside the bearing and decreasing the risk of abnormal wear.

–Applicable Ship Types: It is commonly used in scenarios where environmental protection or noise sensitivity is required, such as small and medium-sized merchant ships, scientific research vessels, military ships, etc.

Limiting Factors: High-load ships (such as large tankers) may still require oil lubrication to cope with extreme pressures.

When the water quality is poor (such as containing a large amount of sediment), the filtration needs to be strengthened; otherwise, it may accelerate the wear of the bearing.

– Material Innovation: Develop composite materials (such as ceramic-reinforced polymers) with higher wear resistance and a lower friction coefficient.

– Intelligent Monitoring: Integrate sensors to monitor the temperature, vibration, and wear status of the bearing in real time, enabling predictive maintenance.

– Hybrid Lubrication Technology: Combine water with a small amount of environmentally friendly lubricant under specific working conditions to further enhance the performance under extreme conditions.

Material List

Different materials can play distinct roles in various fields.

Experimental Report Form

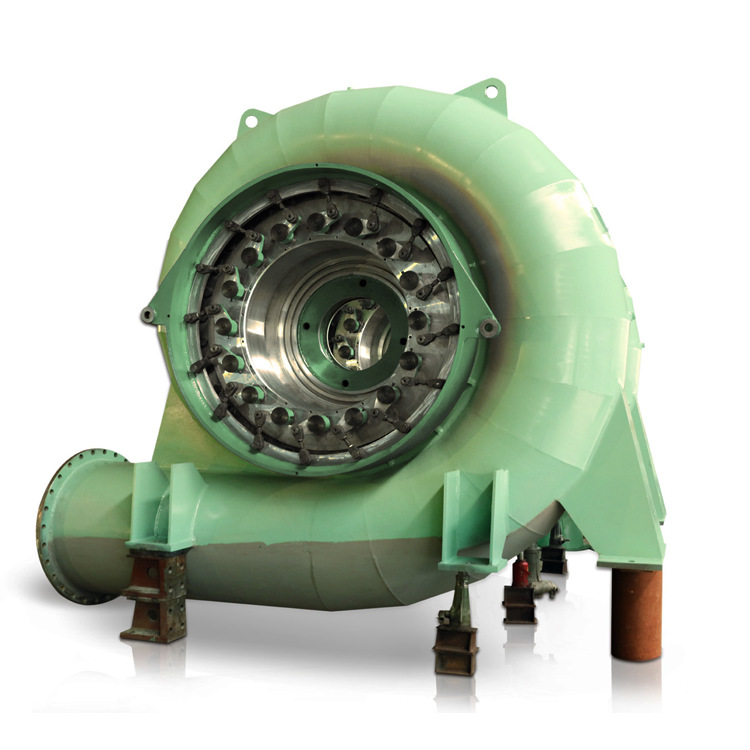

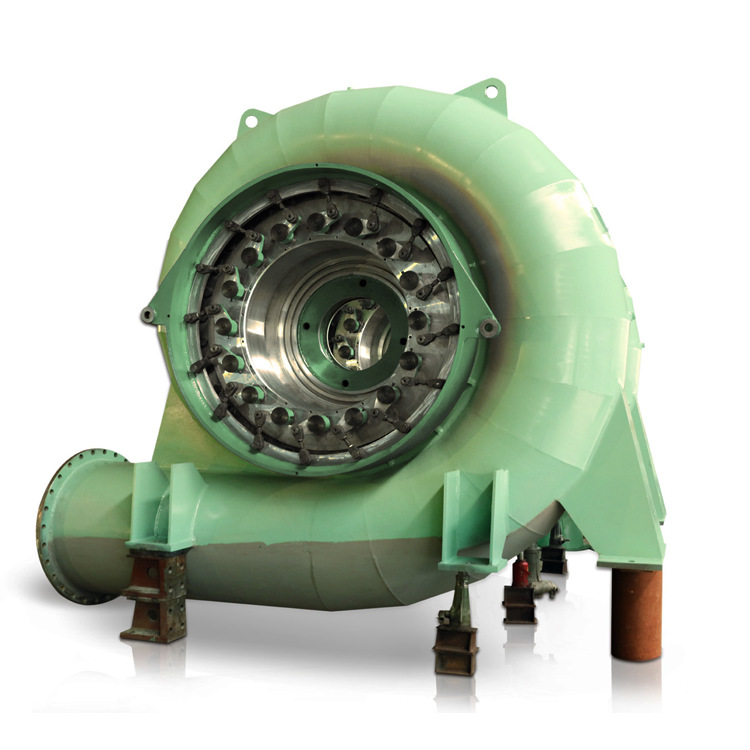

Trbine Bearings

Trbine Bearings

In the field of turbines, SOARLON bearings offer two models, HD-STD and HD-DRY, to meet customers’ different requirements for operating conditions and safety levels. HD-STD features high cost-effectiveness, while HD-DRY has a higher safety level. For small-sized bearings, such as guide vane connecting rod bearings, SOARLON supplies them as integral bearings. For large-sized bearings, such as main shaft guide bearings, SOARLON provides them in the form of bearing shells.

Propeller Shaft Bearings

Propeller Shaft Bearings

HD-STD, HD-DRY, and HD-UWR are SOARLON bearing products specifically designed for propeller shaft systems. Among them, the HD-STD type is suitable for ocean-going vessels sailing in clean water environments. The HD-DRY type is applicable to inland-river vessels navigating in waters with poor water quality and containing sediment. The HD-UWR type is especially suitable for use as the cutter bearings of dredgers. The above-mentioned models can be provided in various structures such as integral, single tapered key, and slat types to meet design requirements.

Stern Roller Bearings

Stern Roller Bearings

Practice has proved that when the HD-STD type SOARLON bearing is used as a stern roller bearing, it not only has a long service life and excellent impact resistance, but can also work normally under the designed ultimate towing force. When the HD-STD is used as a stern roller bearing, according to the design requirements, it can be lubricated with circulating water or grease. Products with a size ranging from 400 to 1500 mm can be customized according to customers’ needs.

Rudder Bearings

Rudder Bearings

For the special working conditions of rudder bearings, such as low-speed swinging and the difficulty in establishing a lubrication film, it is recommended to use the HD-STD type SOARLON bearing. For special vessels with high requirements for reliability, the HD-DRY type SOARLON bearing with a higher safety level can be used. Both of these two types of bearings have self-lubricating properties. Even in the case of water interruption, they can work for a long time, fully meeting the usage requirements of rudder bearings.

Matching Coating for Shaft

Matching Coating for Shaft

SOARLON coating has excellent resistance to the marine environment, and it has good adaptability to working conditions such as sudden temperature rises and drops, sudden pressure changes, and variations in acidic and alkaline environments. Based on years of application experience in engineering cases, the SOARLON coating can protect the stern shaft from seawater corrosion for up to 10 years. Compared with traditional fiberglass winding, the SOARLON coating can be applied on-site, simplifying the construction process and saving costs.

Water Pump Bearings

Water Pump Bearings

In the field of water pumps, the HD-STD type bearing is the most widely used, mainly serving as a guide bearing in vertical water pumps such as deep well long shaft pumps, mixed flow pumps, axial flow pumps, and feed water pumps. The HD-STD type SOARLON bearing allows for a dry start-up time that is more than five times longer than that of similar foreign products, providing a strong guarantee for the highly reliable operation of water pumps under extremely harsh working conditions such as frequent start-stop operations and long periods of water interruption.

Different materials can play distinct roles in various fields.